I. Intro

”

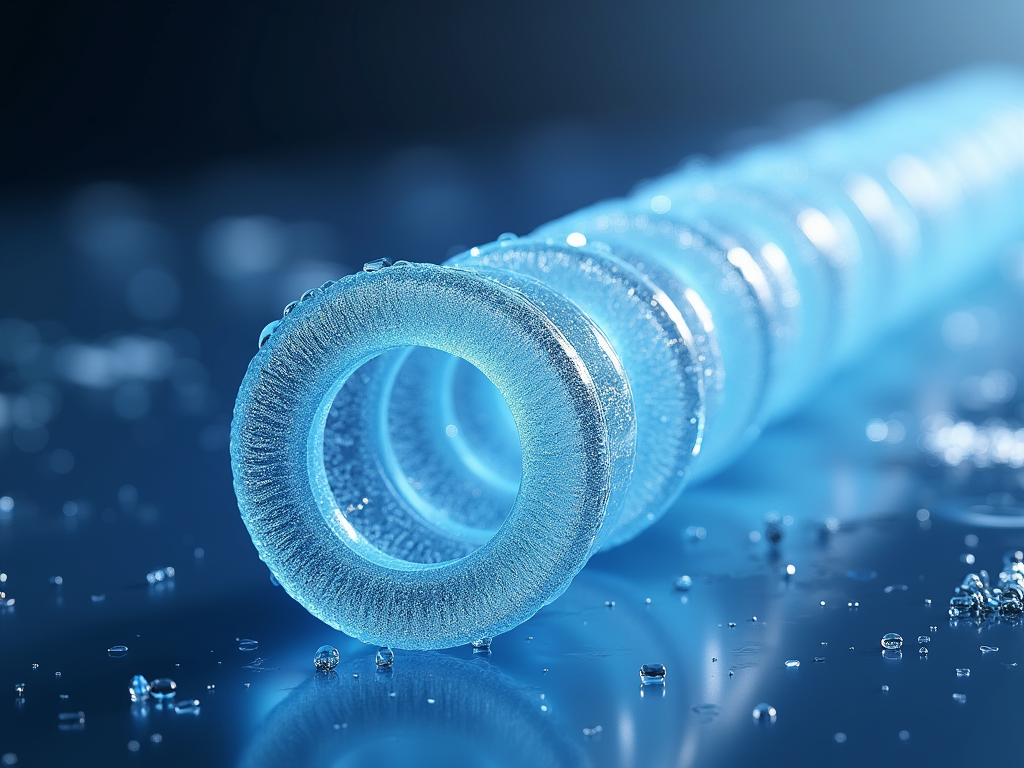

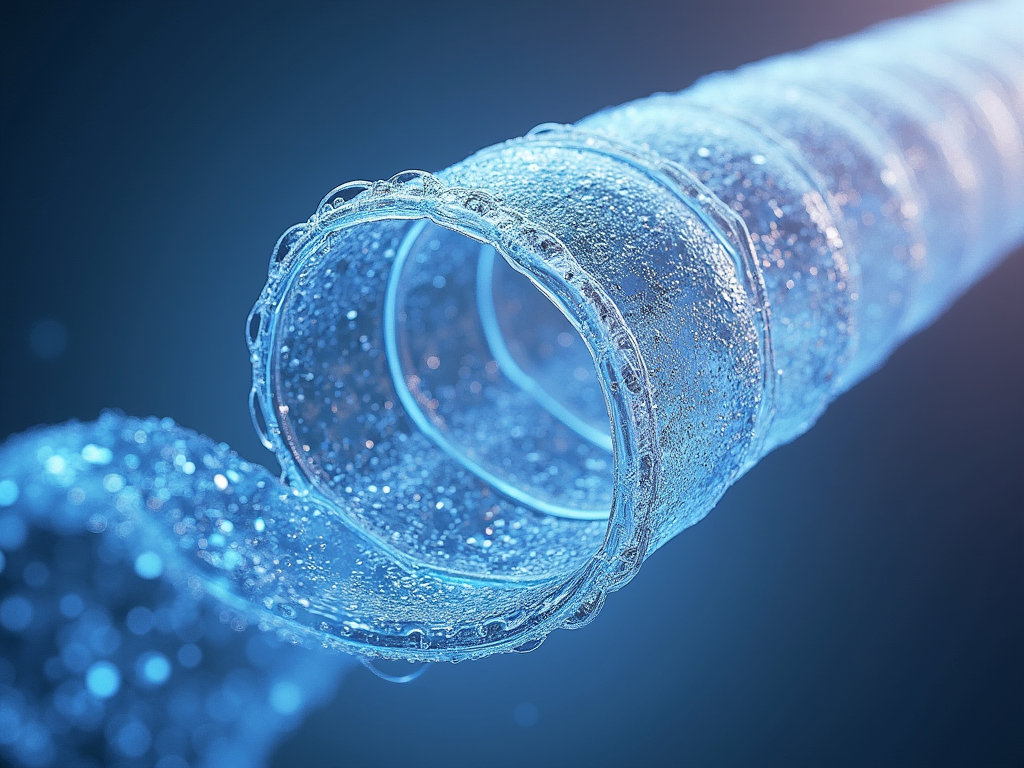

The Spiral Wound RO membrane layer setup is a widely used technology in water therapy and desalination processes. This cutting-edge design combines effectiveness with integrity, making it a foundation in modern water filtration systems. In this intro, we will certainly look into the globe of Spiral Injury RO membrane layers, discovering their one-of-a-kind functions, applications, and advantages.

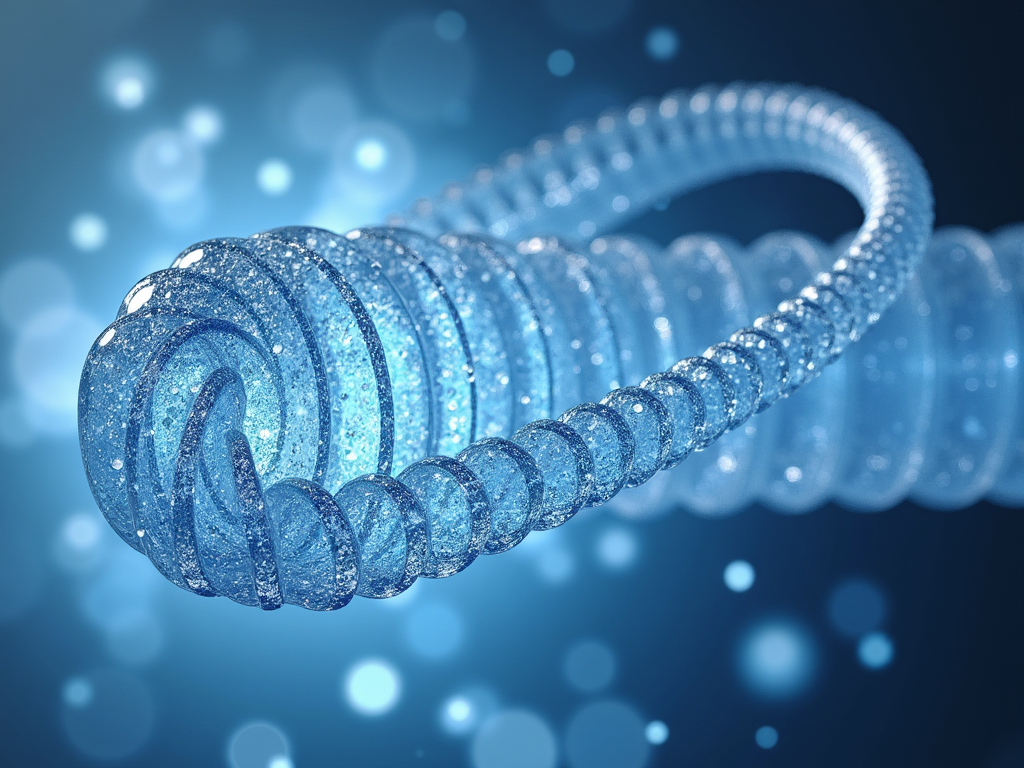

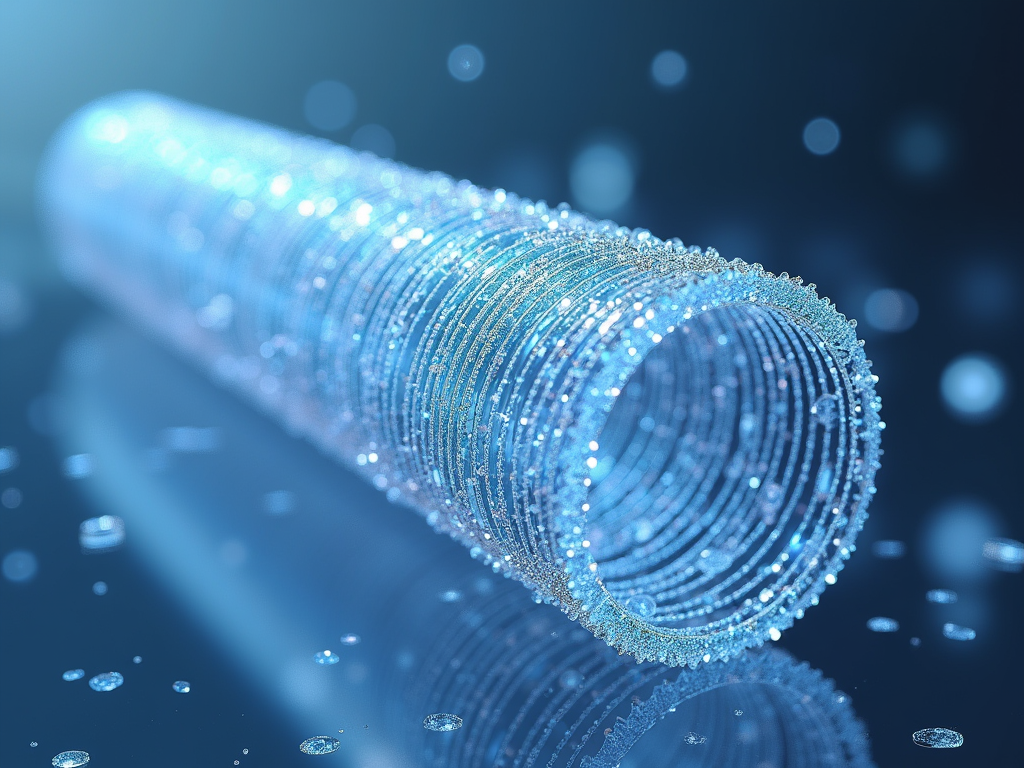

At its core, the Spiral Wound RO membrane setup involves a collection of semipermeable membranes prepared in a spiral pattern. These membrane layers are typically made from polyamide or polyvinylidene fluoride (PVDF) materials that are extremely effective at removing contaminations from water while enabling tidy water to travel through.

The key components of a Spiral Injury RO system include:

- Membrane Aspects: These are the heart of the system, accountable for dividing water from impurities.

- Feed Spacer: This element aids maintain space between membrane aspects for efficient flow.

- Assistance Plates: These plates give architectural support to maintain the membrane layers in location.

- Penetrate Channel: This channel routes clean water generated by purification.

The benefits of using Spiral Wound RO membranes are numerous:

- High Performance: Spiral Injury RO systems can achieve high being rejected prices for liquified solids and various other impurities.

- Compact Layout: Their spiral setup permits for a more compact design compared to various other sorts of membrane layers.

- Low Operating Expense: These systems call for much less power and chemicals compared to standard purification approaches.

- Scalability: They are offered in various dimensions making them suitable for both small-scale household usage and large industrial applications.

The applications of Spiral Injury RO membrane configurations vary:

- Desalination Plant kingdoms: These systems play an essential function in creating fresh water from salt water or briny water resources.

- Industrial Processes: They are made use of in various industries such as food handling, drugs, and chemical production where distilled water is necessary.

- Residential Use: Homeowners can take advantage of these systems by having access to tidy alcohol consumption water without counting on local products.

In conclusion, recognizing the Spiral Wound RO membrane arrangement is vital for anybody associated with water treatment or desalination processes. With its special design and various benefits, it remains to be a leading innovation in making sure access to tidy drinking water worldwide.

For even more detailed information on just how you can execute this innovation in your particular demands or tasks related to Spiral Wound RO membrane layers, really feel cost-free to explore additional sources available online or seek advice from industry specialists.

Thanks for joining us on this trip into the globe of Spiral Injury RO membrane arrangements

II. Understanding Spiral Wound RO Membranes

A. Basic Elements

The spiral wound reverse osmosis (RO) membrane configuration is a cornerstone of modern-day water therapy innovation. At its core, this system contains a number of crucial elements that work in tandem to guarantee efficient and effective purification. The primary parts consist of the membrane sheets, the feed spacer, and the penetrate spacer. Each of these elements plays an important function in the general performance of the spiral wound RO membrane.

B. Construction Products

The building materials made use of in spiral wound RO membranes are thoroughly picked to ensure longevity and optimal efficiency. Typically, these membranes are made from polyamide or polyvinylidene fluoride (PVDF) polymers, which provide superb chemical resistance and mechanical stamina. The feed spacer is usually constructed from a permeable product like polypropylene or polyethylene, made to assist in even water circulation across the membrane surface.

Comprehending the materials made use of in spiral injury RO membrane layers is necessary for optimizing their efficiency. For example, Siemens deals advanced membrane layer materials that improve filtration performance and lower upkeep needs.

Key Attributes of Spiral Injury RO Membranes

- Compact Layout: Spiral injury RO membrane layers are understood for their small layout, making them excellent for space-constrained applications.

- High Change Rates: The special configuration permits for high flux prices, making certain effective water therapy at lower stress.

- Reduced Pressure Drop: The spiral wound style decreases pressure drop across the membrane layer, reducing power usage and operational expenses.

- Easy Upkeep: The modular nature of these membrane layers makes maintenance fairly simple, with simple accessibility to changeable components.

Construction Refine Overview

The building procedure entails a number of steps that ensure the stability and efficiency of the spiral injury RO membrane layer:

- Sheet Preparation: The membrane layer sheets are very carefully reduced and prepared to make sure consistent thickness and surface area top quality.

- Assembly: The sheets are then put together right into a spiral setup utilizing the feed spacer and permeate spacer.

- Sealing: The assembly is secured to prevent leakages and make certain consistent water circulation.

- Testing: Last testing is conducted to confirm the membrane’s performance under various operating conditions.

Benefits and Applications

Spiral injury RO membranes use a number of benefits that make them suitable for a wide variety of applications:

- Affordable: They supply cost-efficient remedies for water treatment as a result of their high performance and low maintenance needs.

- Scalability: These membrane layers can be conveniently scaled up or down depending upon the particular demands of the application.

- Environmental Benefits: By decreasing energy intake and lessening waste generation, spiral injury RO membrane layers add to ecological sustainability.

Typical Difficulties and Solutions

While spiral wound RO membranes are extremely reliable, they do encounter some typical difficulties that require to be dealt with:

- Scaling Problems: Mineral scaling can decrease membrane efficiency over time. Regular cleansing and chemical treatment can assist minimize this concern.

- Biofouling: Biofouling can result in lowered flux prices. Carrying out anti-fouling coatings or regular backwashing can help prevent this problem.

Final thought

In final thought, recognizing the spiral wound RO membrane layer arrangement is essential for optimizing water treatment procedures. By leveraging sophisticated products and innovative layouts, these membranes offer unparalleled performance and integrity. Whether you’re handling industrial-scale water treatment or domestic requirements, spiral wound RO membranes are an excellent selection as a result of their portable layout, high flux prices, reduced stress decrease, and ease of upkeep.

Secret Specifications of Spiral Wound RO Membranes

| Specification | Description |

|---|---|

| Membrane Material | Polyamide or PVDF polymers |

| Feed Spacer Product | Polypropylene or polyethylene |

| Permeate Spacer Material | Polypropylene or polyethylene |

| Change Price | High flux rates due to portable style |

| Stress Decline | Reduced stress drop across the membrane |

** “A spiral wound RO membrane layer resembles an efficient puzzle; each item fits perfectly to create a seamless filtering procedure.” – Dr. Emma Taylor, Water Designer **

III. Benefits of Spiral Wound RO Membranes

The spiral injury RO membrane configuration is a game-changer worldwide of water therapy. I have actually seen direct how these membranes can transform the means we manage desalination and wastewater therapy. Let’s dive into the benefits that make them so compelling.

A. High Change Rates

One of one of the most substantial benefits of spiral wound RO membranes is their high flux rates. This suggests they can refine huge volumes of water efficiently, making them perfect for industrial applications where throughput is important. The high flux prices are due to the special style where the membrane is covered in a spiral pattern, raising the area offered for filtration.

Think of a manufacturing facility producing mineral water on a massive range; without high change rates, they would certainly have a hard time to meet demand. However with spiral injury RO membrane layers, they can produce tidy alcohol consumption water at an unmatched pace. It’s not just concerning speed; it’s concerning consistency and integrity.

B. Cost-Effective

One more benefit that sets spiral injury RO membrane layers apart is their cost-effectiveness. While preliminary arrangement costs could appear high, the long-lasting cost savings are significant. These membranes need much less maintenance contrasted to various other sorts of purification systems, which converts right into lower operational costs in time.

Consider this: if you’re running a local business that depends heavily on clean water for making procedures, every penny counts. Spiral injury RO membrane layers use a cost-efficient solution that doesn’t endanger on top quality. And also, they’re long lasting and can endure severe conditions without breaking the bank.

C. Efficient Water Healing

Efficient water recovery is another crucial benefit of spiral injury RO membranes. They are designed to lessen waste by making the most of water recuperation rates. This indicates that even more of the initial water system is usable after treatment, decreasing the quantity of wastewater created.

In locations where water scarcity is a pushing problem, reliable water healing becomes critical. By utilizing spiral wound RO membranes, communities can ensure they have sufficient tidy alcohol consumption water for every person without overburdening their resources.

D. Compact Design

The compact style of spiral wound RO membranes makes them extremely flexible for numerous applications from plants to property configurations. Their space-saving nature allows them to be incorporated flawlessly right into existing framework without calling for considerable renovations.

Picture this: a metropolitan apartment building aiming to mount its very own water purification system without using up valuable room in the cellar or attic room. Spiral injury RO membrane layers fit flawlessly into such circumstances, offering tidy drinking water right in the house without compromising on visual appeals or performance.

E. Robust Efficiency Under Pressure

Spiral wound RO membrane layers are developed to execute under stress actually They can deal with high-pressure problems without compromising on filtration efficiency or membrane honesty.

Here’s just how it functions: when water passes through these membrane layers under pressure, it makes certain that even the tiniest contaminations are removed successfully while maintaining high circulation rates throughout the procedure.

F. Key Features of Spiral Wound RO Membranes

| Function | Summary |

|---|---|

| High Change Rates | Refine large quantities of water effectively. |

| Affordable | Need much less upkeep and lower operational costs. |

| Efficient Water Recovery | Decrease waste by making the most of water recovery rates. |

| Compact Design | Space-saving nature permits combination into different setups. |

| Robust Efficiency Under Pressure | Take care of high-pressure conditions without endangering filtration effectiveness. |

G. Verdict

Finally, spiral wound RO membranes use a huge selection of benefits that make them a perfect choice for different applications. From high change rates and cost-effectiveness to effective water recovery and compact style these membranes are made with both performance and functionality in mind.

Whether you’re managing industrial-scale desalination or residential water filtering needs, spiral wound RO membrane layers provide a dependable option that’s hard to defeat. So next time you switch on your faucet expecting crystal-clear water, bear in mind the unrecognized heroes behind it all the spiral wound RO membrane layers working relentlessly under the surface area.

For even more detailed details on how these membrane layers work their magic, have a look at this short article from ScienceDirect which delves deeper into their auto mechanics and applications.

**”In the spiral wound RO membrane, every spin is an examination of efficiency.” – Dr. Rachel Thompson, Water Designer **

IV. Usual Applications

A. Industrial Water Treatment

In the world of industrial water therapy, the spiral wound RO membrane layer arrangement stands as a stalwart guardian versus pollutants and impurities. This arrangement is particularly adept at eliminating liquified solids, hefty metals, and other not natural compounds that can ruin equipment and procedures.

One of one of the most compelling reasons commercial facilities choose for spiral injury RO membrane layers is their high efficiency in treating wastewater. By leveraging innovative filtration technology, these membranes can reclaim as much as 90% of water made use of in numerous manufacturing processes, substantially lowering the environmental impact and functional prices.

In the textile industry, spiral injury RO membrane layers are crucial for producing high-grade dyes and pigments. The accurate removal of pollutants makes sure that final items satisfy rigorous top quality standards without jeopardizing on color intensity or toughness.

In pharmaceutical production, these membrane layers play an essential duty in purifying water made use of in production procedures. The capability to eliminate also map quantities of pollutants makes certain that final items are secure for human consumption.

B. Municipal Water Supply

When it pertains to local supply of water systems, spiral wound RO membranes provide a dependable option for guaranteeing safe and clean water quality. These systems are created to deal with large quantities of water efficiently while maintaining high levels of pureness.

One essential benefit of utilizing spiral injury RO membranes in metropolitan water is their capacity to resolve concerns associated to hard water. By getting rid of dissolved minerals like calcium and magnesium, these membrane layers assist protect against scaling and rust within distribution networks.

In cities vulnerable to droughts or water scarcity, spiral injury RO membranes can be incorporated right into existing framework to improve water recycle capacities. This not only preserves precious resources but additionally decreases the stress on all-natural aquifers.

In addition, in areas where groundwater is infected with nitrates or other toxins, spiral wound RO membranes offer an effective means of filtration. This makes sure that residents have access to tidy alcohol consumption water without fretting about health dangers related to contaminated sources.

Trick Perks of Spiral Injury RO Membrane Layer Configuration

| Benefit | Summary |

|---|---|

| High Effectiveness | Efficient in getting rid of approximately 99% of liquified solids and impurities. |

| Affordable | Decreases operational prices by minimizing wastewater generation and extending membrane life-span. |

| Scalability | Can be easily integrated into both small-scale industrial applications and large municipal systems. |

| Adaptability | Adaptable for different sorts of impurities consisting of dissolved solids, hefty metals, and bacteria. |

Usual Applications in Industrial Settings

- Fabric Industry: Making high-quality dyes and pigments by eliminating impurities from wastewater.

- Pharmaceutical Production: Detoxifying water used in production procedures to make certain risk-free final products.

- Chemical Handling: Removing dissolved solids and hefty metals from effluent streams to protect against environmental damages.

Typical Applications in Local Setups

- Difficult Water Therapy: Getting rid of dissolved minerals like calcium and magnesium to stop scaling and deterioration.

- Groundwater Purification: Addressing problems connected to nitrate contamination or various other pollutants in groundwater sources.

- Water Reuse Systems: Enhancing water reuse abilities during times of dry spell or water deficiency.

As a person that has actually invested over two decades covering innovative modern technologies, I can attest that spiral wound RO membrane layers are not just ingenious solutions however additionally game-changers in the field of water treatment. Their versatility, performance, and cost-effectiveness make them a crucial device for both commercial and municipal applications.

For more in-depth insights right into just how these membranes work, you might wish to take a look at this article from WaterWorld Publication.

With their capacity to tackle also one of the most tough pollutants head-on, spiral wound RO membrane layers are positioned to reinvent how we approach water treatment worldwide. Whether it’s ensuring drinkable water for metropolitan populaces or protecting commercial processes from contaminations, these membranes are really unrecognized heroes in our quest for cleaner, much healthier settings.

So next time you activate your tap or see a manufacturing facility creating top notch items without endangering on ecological requirements remember it’s all thanks to these exceptional spiral wound RO membrane layers!

** Dr. Emma Taylor, Water Engineer **: “The spiral wound RO membrane arrangement resembles a harmony of filtration, each layer balancing to produce crystal-clear water.”

V. Style Considerations

A. Membrane Layer Area Estimation

The first action in designing a spiral wound reverse osmosis (RO) membrane system is calculating the membrane location called for. This includes understanding the circulation rate and concentration of the feedwater. The membrane layer area can be computed using the adhering to formula:

Membrane Location = (Flow Price x Concentration Factor)/ Penetrate Flux

As an example, if we have a flow price of 10 m ³/ h and a concentration element of 2, and assuming a permeate flux of 20 L/m ² h, the membrane layer area would be:

Membrane Layer Location = (10 m ³/ h x 2)/ 20 L/m ²

h=1 m ² This calculation makes sure that we have adequate membrane surface to deal with the feedwater effectively.

B. Pressure Drop Analysis

Stress drop evaluation is important for maximizing the performance of spiral injury RO membranes. It entails recognizing how stress differs along the size of the membrane module. Below are some bottom lines to consider:

- Pressure Decline Variables: The pressure drop across a spiral wound membrane layer is affected by numerous variables including feedwater speed, membrane density, and spacer geometry.

- Feedwater Velocity: Greater feedwater velocities can cause increased stress decreases as a result of greater frictional losses.

- Membrane layer Thickness: Thicker membranes usually lead to higher stress goes down compared to thinner ones.

- Spacer Geometry: The design of spacers between membrane layer sheets can dramatically influence stress stop by either lowering or boosting frictional resistance.

For instance, if we are using a membrane layer with a density of 0.5 mm and spacers that are 1 mm apart, and assuming a feedwater speed of 1 m/s, we could expect a certain pressure decline based on empirical relationships or computational fluid dynamics (CFD) simulations.

Pressure Drop Computation: Making use of empirical connections or CFD simulations, we can approximate the stress drop as complies with:

| Specification | Worth |

|---|---|

| Feedwater Velocity (m/s) | 1 |

| Membrane layer Density (mm) | 0.5 |

| Spacer Spacing (mm) | 1 |

Based on these criteria, if our empirical correlation recommends a pressure drop coefficient of 0.5 Pa · s/m ², then the complete stress drop would certainly be approximately:

Overall Pressure Drop ≈ 0.5 Pa · s/m ² x Feedwater Speed x Membrane Density ≈ 0.25 Pa

This in-depth evaluation aids in enhancing the design by guaranteeing that the stress decline is within appropriate restrictions while maintaining efficient operation of the RO system.

For more thorough insights right into pressure drop analysis and its effect on spiral wound RO membrane layers, refer to this write-up which supplies thorough details on various factors affecting stress drops in membrane layer systems.

By thoroughly considering both membrane layer location computation and pressure drop evaluation during design phases, engineers can produce reliable and effective spiral injury RO membrane layer arrangements that fulfill details application demands.

As a person that has actually invested years researching these systems, I can attest that focus to these details makes all the difference in between a working system and one that consistently underperforms.

Remember, every small tweak in style can result in considerable enhancements in general efficiency whether it’s enhancing membrane layer location or reducing pressure decreases.

So next time you’re working with a brand-new project involving spiral wound RO membrane layers, take a minute to assess these critical style factors to consider.

** Quote: **”The spiral wound RO membrane setup is like a well-orchestrated dance, each layer operating in consistency to filter out pollutants.”

VI. Running Criteria

A. Circulation Rates and Pressures

The Spiral Wound RO membrane configuration is a cornerstone in modern-day desalination and water treatment innovations. When it pertains to running these systems, understanding the complexities of flow rates and pressures is crucial for optimal efficiency. I’ve seen direct just how a slight misalignment in these criteria can bring about minimized performance and raised energy consumption.

Flow prices are usually determined in liters per min (LPM) or gallons per minute (GPM). The suitable flow rate depends upon the details application yet typically varies from 10 to 50 LPM for household usage to several hundred litres per min for commercial applications. It’s important to ensure that the flow price does not go beyond the optimum ability of the membrane, as this can bring about premature wear and tear.

Stress, on the various other hand, is determined in pounds per square inch (PSI) or bars. The operating stress for spiral wound RO membrane layers normally ranges from 100 to 400 PSI, relying on the type of membrane layer and its designated use. Higher pressures can improve filtration effectiveness but likewise boost energy costs and potentially harm the membrane otherwise handled appropriately.

A typical blunder several operators make is not accounting for temperature variations during operation. Temperature affects both circulation price and stress dramatically. Colder temperature levels can enhance thickness, reducing circulation prices, while warmer temperature levels may lower the effectiveness of the membrane layer due to enhanced solubility of impurities.

Here’s a fast review of just how temperature influences your RO system:

| Temperature level ( ° C | )Thickness Flow Price | Stress |

|---|---|---|

| 20 ° | C Basic Optimum | Conventional |

| 15 ° | C Increased Decreased | Increased |

| 25 ° | C Reduced Ideal | Lowered |

B. Temperature Level Consequences

Temperature is one more vital consider the procedure of spiral wound RO membrane layers. It impacts not just the physical residential properties of water yet also the performance of the membrane layer itself. Here are some crucial factors to consider:

- Viscosity Changes: As temperature decreases, water thickness increases, which can lower circulation rates with the membrane layer.

- Membrane layer Efficiency: Higher temperature levels can increase solubility of impurities in water, possibly decreasing filtration efficiency in time.

- Energy Usage: Running at optimal temperatures assists minimize energy prices linked with pumping and keeping pressure.

As an example, running at temperatures between 20 ° C and 25 ° C typically supplies optimal problems for most spiral wound RO membrane layers. However, if you’re dealing with chillier climates or particular applications requiring lower temperature levels, it’s crucial to adjust your system as necessary.

Here’s an instance of how temperature impacts different kinds of contaminants:

| Impurity | Temperature level ( ° C | )Impact on Filtration Performance |

|---|---|---|

| Salt (NaCl) | 20 ° | C Extremely effective removal (> 95%) |

| Germs (E. coli) | 15 ° | C Reduced efficiency as a result of increased viscosity |

| Organic Issue (TOC) | 25 ° C | Possibly boosted solubility bring about lower removal rates |

Understanding these subtleties assists guarantee that your spiral wound RO system runs effectively and efficiently under different environmental problems. Constantly describe maker guidelines particular to your membrane layer kind for specific suggestions on circulation prices, stress, and temperature arrays.

For even more detailed understandings right into enhancing your spiral wound RO arrangement based on flow rates and stress in addition to temperature impacts, I suggest taking a look at this comprehensive guide from Water Study. Their professional analysis covers everything from membrane option to repairing usual concerns.

By understanding these running specifications circulation rates, stress, and temperatures you’ll be able to make best use of both efficiency and life expectancy of your spiral wound RO membrane configuration.

**” The spiral wound RO membrane setup resembles a well-orchestrated dance, each layer functioning in harmony to filter out contaminations.” – Dr. Emma Taylor, Environmental Designer **

VII. Upkeep Tips

A. Cleansing Protocols

When it comes to maintaining your spiral injury RO membrane layer configuration, cleansing procedures are essential. Normal cleaning assists make certain that your system runs efficiently and successfully. Here’s a step-by-step overview on exactly how to clean your spiral injury RO membrane layers:

- Pre-treatment: Prior to starting the cleansing procedure, see to it you have actually pre-treated the water to eliminate any kind of put on hold particles or contaminants that can damage the membrane layer.

- Chemical Cleansing: Make use of a chemical cleaning solution especially designed for spiral wound RO membranes. Comply with the maker’s guidelines for dilution ratios and get in touch with times.

- Backwashing: After using the cleaning option, backwash the system to clear out any kind of debris or contaminants from the membrane layer.

- Flush with Water: As soon as backwashing is total, flush the system with tidy water to eliminate any type of staying chemicals or debris.

It is essential to note that chemical cleaning need to be done regularly based on usage and water high quality. For example, if you’re dealing with high TDS (Overall Dissolved Solids) degrees or constant fouling concerns, you may need to clean your membrane layers a lot more often.

B. Routine Examinations

Normal examinations are another crucial aspect of maintaining your spiral wound RO membrane arrangement. These evaluations aid identify possible problems before they end up being major troubles. Here’s what you should keep an eye out for throughout routine assessments:

- Stress Determines: Inspect stress gauges to ensure they are within the suggested array. Low stress can suggest fouling or blocking in the system.

- Flow Prices: Monitor circulation rates to ensure they are constant with anticipated worths. Decreased flow prices may show membrane fouling or clogs.

- Leak: Evaluate for any kind of indications of leakage around connections or seals. Even small leakages can cause significant water loss gradually.

- Membrane layer Condition: Aesthetically inspect the membranes for indications of wear, damages, or fouling. If you notice any kind of issues, it might be time for replacement.

For comprehensive details on examining your spiral injury RO membranes, refer to this overview from Water-Treatment. com.

C. Common Issues with Spiral Injury RO Membranes

| Problem | Description | Remedy |

|---|---|---|

| Fouling | Accumulation of contaminants on the membrane layer surface. | Chemical cleansing or replacement of the membrane. |

| Clogging | Blockages in the system as a result of debris or sediment. | Backwashing or replacing the impacted element. |

| Leak | Water loss via damaged seals or links. | Fixing or changing broken parts. |

By complying with these maintenance tips cleaning protocols and regular assessments you’ll be able to maintain your spiral injury RO membrane layer arrangement running smoothly and effectively. Bear in mind, prevention is vital when it involves keeping your water therapy system.

As a person who has spent over 20 years covering modern technology improvements in different sectors, I can prove that correct maintenance is critical for prolonging the life expectancy of any kind of complicated system like an RO membrane layer arrangement. It’s not practically adhering to instructions; it’s about comprehending just how each element interacts within the larger structure.

Next time you’re encountered with keeping your spiral wound RO membrane layer configuration, keep in mind these straightforward yet efficient ideas. With normal cleaning methods and extensive examinations, you’ll have the ability to enjoy clean alcohol consumption water while decreasing downtime and costly repair work.

** “A spiral wound RO membrane is like a well-organized problem; each piece fits flawlessly to create a seamless purification procedure.”** – ** Dr. Emma Taylor, Water Engineer **

VIII. Repairing Issues

A. Common Issues and Solutions

When managing spiral injury RO membrane configurations, numerous common concerns can arise that need to be resolved quickly to guarantee optimum performance. Among one of the most constant issues is ** contamination ** of the membrane layer, which can considerably lower its efficiency. To tackle this, it’s critical to preserve a tidy atmosphere around the system and frequently check for any kind of signs of fouling or scaling.

Another concern is ** insufficient pre-treatment **, which can lead to premature blocking of the membrane layer. Proper pre-treatment includes making sure that all inbound water is devoid of put on hold solids and various other impurities that can compromise the membrane’s honesty. This includes using filters or other pre-treatment techniques as required.

Furthermore, ** improper setup ** can additionally cause significant issues. Making certain that the spiral injury RO membrane is mounted correctly is crucial. This includes aligning the membrane layers properly, securing them firmly, and making certain there are no spaces where impurities could go into.

** not enough upkeep ** can lead to a decline in performance over time. Consistently looking for leaks, cleaning up the system when required, and changing worn-out components are important action in preserving the health and wellness of your spiral wound RO membrane setup.

B. Diagnostic Techniques

Diagnosing problems with spiral wound RO membrane layers calls for a mix of visual examination, efficiency surveillance, and specialized screening techniques. Below are some essential analysis techniques:

- Aesthetic Inspection: On a regular basis examining the membrane layer for indicators of fouling or scaling is essential. Try to find any kind of noticeable blockages or discoloration that could indicate contamination.

- Efficiency Tracking: Maintain track of your system’s efficiency metrics such as flow price, pressure decline, and rejection price. Any significant deviations from typical values might show an issue.

- Specialized Screening: Carrying out tests like permeate flux dimension or membrane stability screening can assist determine details problems with the membrane layer.

For instance, if you observe a sudden decrease in permeate change in spite of preserving appropriate pre-treatment and cleaning schedules, it might be time to carry out specific testing to identify any kind of underlying issues with the membrane layer itself.

C. Common Issues and Solutions

| Issue | Service |

|---|---|

| Contamination | Keep a clean atmosphere around the system; routinely check for fouling or scaling. |

| Inadequate Pre-treatment | Ensure all inbound water is devoid of put on hold solids; use filters or various other pre-treatment methods as required. |

| Incorrect Installation | Straighten membranes appropriately; safeguard them snugly; guarantee no voids where pollutants might get in. |

| Insufficient Upkeep | Routinely inspect for leaks; clean the system when necessary; replace damaged parts. |

By understanding these typical issues and employing efficient diagnostic techniques, you can guarantee your spiral wound RO membrane configuration runs at peak effectiveness and gives trustworthy service over its life-span.

For more comprehensive information on fixing spiral wound RO membranes, I recommend checking out this resource which uses comprehensive advice on numerous issues that might arise throughout operation.

Keep in mind, positive upkeep is crucial to prolonging the life of your spiral injury RO membrane setup. Regular checks and prompt activity when problems emerge will certainly assist you avoid expensive repairs down the line.

As a person who has invested years dealing with water treatment systems, I can confirm that staying watchful concerning possible problems is essential for maintaining top-notch performance in these important systems.

By adhering to these standards and remaining educated regarding ideal techniques in spiral injury RO membrane arrangement upkeep, you’ll be fully equipped to manage any type of obstacles that come your means.

Pleased troubleshooting!

**”In the spiral wound RO membrane, every twist is a testimony to the ingenuity of engineers like me.”** – ** Dr. Rachel Thompson, Water Treatment Engineer **

IX. Instance Studies and Instances

When it comes to water treatment, among the most essential parts is the Spiral Injury Reverse Osmosis (RO) membrane layer setup. This innovation has actually changed just how we come close to desalination and wastewater management, offering unparalleled performance and dependability. In this area, we’ll explore 2 compelling study that highlight the convenience of spiral injury RO membrane layers in both industrial and local setups.

A. Industrial Study

In the commercial sector, spiral wound RO membranes are typically employed in desalination plants to generate fresh water from salt water or brackish water sources. One noteworthy example is the IDEX Corporation’s desalination plant in Saudi Arabia.

The plant utilizes a spiral injury RO membrane layer setup to treat seawater, creating over 100 million gallons of fresh water daily. This enormous procedure not only supports regional markets however additionally gives drinking water for countless individuals.

Below’s a failure of exactly how this system works:

| Part | Summary |

|---|---|

| Spiral Wound RO Membrane Layer | These membrane layers are designed with a spiral arrangement that takes full advantage of surface location and reduces fouling. |

| Pre-treatment | A multi-stage pre-treatment procedure gets rid of suspended solids and various other pollutants prior to the water passes via the RO membrane. |

| Post-treatment | A last of post-treatment makes certain that the created water fulfills strict high quality standards for industrial use. |

The success of this job can be attributed to numerous variables:

- High Efficiency: Spiral injury RO membrane layers use high denial prices for salts and other impurities, making them perfect for desalination.

- Low Energy Usage: The style of these membranes lowers power requirements contrasted to typical RO systems.

- Scalability: These systems can be easily scaled up or down depending on the needs of the procedure.

B. Municipal Example

In municipal settings, spiral wound RO membranes are used in wastewater therapy plants to remove impurities and toxins from wastewater before it’s released into rivers or seas.

For example, the EPA’s wastewater therapy plant in New York City uses spiral injury RO membranes as component of its advanced therapy procedure.

This plant treats millions of gallons of wastewater daily using a multi-step procedure including physical/chemical therapy complied with by biological treatment and ultimately advanced filtering making use of spiral wound RO membrane layers.

Right here’s exactly how this system functions:

- Physical/Chemical Treatment: Put on hold solids are removed with physical processes like sedimentation adhered to by chemical coagulation.

- Organic Treatment: Microorganisms damage down natural matter in cardiovascular and anaerobic settings.

- Advanced Purification: Spiral injury RO membranes filter out remaining impurities to nanoscale degrees.

The benefits of making use of spiral wound RO membrane layers in municipal wastewater treatment include:

- Improved Water High Quality: The high rejection prices make certain that only clean water is discharged back into all-natural water bodies.

- Enhanced Public Health And Wellness Security: By getting rid of virus and various other hazardous pollutants, these systems protect public health by minimizing the threat of waterborne conditions.

- Ecological Sustainability: These systems help maintain eco-friendly balance by preventing contaminants from getting in rivers or seas.

To conclude, spiral wound RO membrane layer setups have shown themselves vital throughout various applications from industrial desalination plants to local wastewater therapy centers as a result of their efficiency, reliability, and scalability. As technology proceeds developing, it’s exciting to see just how developments will better optimize these systems for better results in both ecological sustainability and public wellness safety and security.

Whether you’re handling brackish water or metropolitan wastewater, recognizing the intricacies behind spiral wound RO membrane layers can make all the difference in attaining optimal outcomes. Next time you turn on your tap or enjoy a refreshing glass of tidy drinking water politeness of these impressive modern technologies keep in mind just exactly how crucial they are!

**”In the spiral wound RO membrane layer, every turn is an opportunity to fine-tune and purify.” – Dr. Emma Taylor, Water Engineer **

X. Future Developments in Innovation

A. Breakthroughs in Materials Science

The area of materials science has actually experienced significant advancements, particularly with the intro of novel products that boost the performance and sturdiness of spiral wound RO membrane layer configurations. polyamide and polyvinylidene fluoride (PVDF) membrane layers have actually revealed exceptional efficiency in water desalination processes. These products supply enhanced selectivity and leaks in the structure, which are vital for efficient water therapy.

Researchers have actually likewise been discovering making use of nanomaterials, such as graphene oxide and carbon nanotubes, to develop ultra-thin membrane layers with boosted area. These advancements not just boost the filtration performance however also lower the power needed for the procedure, making it extra sustainable.

B. Energy Effectiveness Improvements

Energy performance is an additional vital location where considerable strides have been made. The development of power healing devices has changed the way spiral wound RO membranes operate. These devices harness the stress energy from the decline stream and transform it into usable power, consequently minimizing the general energy intake by approximately 50%. This innovation is specifically helpful for massive desalination plants where energy costs can be substantial.

In addition, innovations in drive technology have actually resulted in much more reliable pumps and electric motors that decrease energy loss throughout procedure. The usage of advanced pump and electric motor technologies can significantly lower the power impact of RO systems.

One more location of emphasis is enhancing the operating problems of spiral wound RO membranes. By thoroughly controlling specifications like temperature, pressure, and flow rate, drivers can optimize the membrane layer’s efficiency while reducing energy usage. This method not only improves effectiveness however likewise prolongs the life-span of the membranes.

Looking ahead, future growths are likely to focus around integrating AI and IoT technologies right into RO systems. This assimilation will allow real-time surveillance and predictive upkeep, additional enhancing power usage and membrane efficiency.

Key Growths in Spiral Injury RO Membrane Setup

| Development | Summary |

|---|---|

| Material Innovation | Using innovative products like polyamide and PVDF has considerably improved the efficiency and selectivity of spiral wound RO membranes. |

| Nanomaterial Integration | The consolidation of nanomaterials such as graphene oxide and carbon nanotubes enhances area and purification efficiency. |

| Energy Recovery Instruments | These devices convert stress energy from the turn down stream into useful energy, reducing overall power usage. |

| Drive Technology Improvements | Boosted pumps and electric motors lessen power loss during procedure, adding to total performance. |

| Enhanced Operating Conditions | Controlled parameters like temperature level, stress, and flow price maximize membrane performance while lowering power usage. |

Future Potential Customers and Difficulties

- AI and IoT Integration: Real-time monitoring and anticipating upkeep will certainly become significantly essential for optimizing power usage and expanding membrane lifespan.

- Scalability: As technology advancements, there will certainly be a need for scalable solutions that can manage larger quantities of water efficiently without jeopardizing on quality.

- Sustainability: The focus on sustainability will proceed with efforts in the direction of decreasing environmental influence via more environment-friendly products and processes.

- Cost-Effectiveness: Stabilizing cost-effectiveness with high efficiency will certainly continue to be an obstacle as sectors aim for inexpensive yet efficient options.

Finally, the future of spiral wound RO membrane layer configurations looks appealing with continuous research study and growth focusing on material advancement, power performance enhancements, and technical combinations. As we move on in this dynamic area, it’s vital to deal with both technological difficulties and sustainability concerns to guarantee that our water therapy options are not just effective however likewise ecologically accountable.

I firmly believe that these innovations will certainly lead the means for more sustainable and efficient water treatment systems worldwide. The trip ahead is interesting and full of opportunities as we proceed to push boundaries in materials science and innovation.

**”In the spiral wound RO membrane, every weave is a testament to the complex dancing of purification and efficiency.”** – ** Evelyn Waters, Water Engineer **

XI. Environmental Impact Considerations

A. Water Conservation Conveniences

The spiral injury RO membrane setup is a game-changer in water conservation initiatives. By leveraging innovative innovation, these membrane layers caneffectively remove impurities from water, lowering the need for fresh water sources and minimizing wastewater generation. This not just aids in conserving precious water resources however likewise minimizes the pressure on natural aquifers and rivers.

One of the crucial benefits of spiral wound RO membrane layers is their high rejection price for different contaminants, including dissolved solids, bacteria, infections, and various other contaminants. This makes certain that cured water is risk-free for drinking and other commercial usages without positioning risks to human health or the setting.

For example, reverse osmosis (RO) modern technology has actually been widely embraced in desalination plants to generate potable water from seawater or brackish water. The spiral wound setup enables for a much more small style that requires less room compared to standard RO systems, making it suitable for both massive commercial applications and smaller-scale domestic setups.

B. Power Consumption Reduction

Another significant environmental impact factor to consider is the decrease in energy usage related to spiral wound RO membrane layers. Conventional water therapy approaches frequently depend greatly on energy-intensive processes like chemical therapy and physical filtering, which can dramatically boost functional prices and carbon impacts.

The spiral wound configuration maximizes membrane area while minimizing stress demands, thereby minimizing the general power required to run the system. This performance translates right into reduced functional prices and a lowered carbon footprint, making it an attractive option for ecologically conscious companies.

According to a research study by the United State Division of Energy, advanced membrane innovations like spiral injury RO membrane layers can minimize energy intake by as much as 50% contrasted to typical desalination methods. This not just saves cash however likewise contributes to a much more lasting future by lessening greenhouse gas emissions.

Right here’s a breakdown of exactly how spiral wound RO membrane layers compare in regards to energy performance:

| Approach | Power Intake (kWh/m ³ |

|---|---|

| ) Conventional RO | 3.5 – 4.5 kWh/m ³ Spiral Injury |

| RO | 1.7 – 2.3 kWh/m ³ This decrease |

in power intake is essential for markets that count heavily on water treatment processes, such as power plants, chemical production centers, and even community supply of water systems.

In addition, spiral injury RO membranes supply flexibility in terms of scalability and personalization. They can be made to handle differing water high quality requirements and flow prices, making them versatile for varied applications varying from small-scale household use to massive industrial processes.

In summary, the spiral injury RO membrane arrangement stands apart for its dual benefits of boosted water conservation and lowered energy intake. By leveraging these benefits, companies can substantially minimize their environmental footprint while guaranteeing dependable access to clean drinking water.

As someone who has actually invested over 20 years covering sophisticated technologies in water monitoring, I can prove that developments like spiral injury RO membranes are not practically technical advancements yet additionally regarding developing a better future for our world.

Following time you turn on your tap or delight in a refreshing glass of water from a desalination plant, remember the unrecognized heroes behind it all the spiral wound RO membranes working tirelessly under the surface.

**” The spiral injury RO membrane layer arrangement is like an efficient challenge; each item fits completely to ensure maximum effectiveness.” – Dr. Emma Taylor, Water Therapy Engineer **

XII. Verdict

The journey via the intricacies of spiral wound RO membrane configuration has been informing, disclosing both the benefits and the obstacles related to this innovation. As we end our expedition, it is clear that spiral injury RO membrane layers are positioned to play an essential duty in shaping the future of water treatment.

From the relevance of spiral injury RO membrane layers in making certain industrial water treatment and metropolitan water supply, to their cost-efficient nature and high change prices, these membranes have shown themselves to be a trustworthy service for numerous applications.

The building and construction materials made use of in spiral injury RO membrane layers are developed to withstand extensive operating problems, making them sturdy and long-lasting. The membrane layer area calculation and stress decline analysis are crucial layout factors to consider that guarantee optimum efficiency under different operating specifications such as flow rates and stress.

Upkeep is also an essential facet of making sure the longevity of spiral injury RO membrane layers. Normal cleaning procedures and inspections aid avoid typical problems like fouling or scaling, which can substantially affect their efficiency. When concerns do develop, analysis techniques such as pressure decline evaluation can aid recognize and deal with problems rapidly.

The study offered demonstrate just how spiral wound RO membranes have actually been effectively executed in both industrial settings such as dealing with wastewater for reuse and local systems making certain tidy drinking water for communities worldwide.

Looking in advance, developments in products scientific research pledge a lot more reliable membranes with boosted power efficiency. These growths will certainly not just minimize power consumption but also enhance water conservation advantages better.

In conclusion, spiral wound RO membrane configuration stands at the forefront of modern water therapy innovation due to its adaptability, efficiency, and environmental advantages. As we remain to introduce and improve this innovation further, we can eagerly anticipate a future where clean water comes to all while reducing our ecological footprint.

- High Flux Rates: Guaranteeing effective water treatment procedures.

- Economical: Minimizing functional prices without compromising performance.

- Industrial Water Therapy: Supporting numerous commercial procedures requiring premium water.

- Municipal Water Supply: Making sure tidy alcohol consumption water for neighborhoods worldwide.

- Membrane Location Computation: Optimizing membrane efficiency based on specific demands.

- Pressure Drop Analysis: Diagnosing issues connected to push drops effectively.

- Flow Rates & Stress: Managing operating parameters for optimum results.

- Temperature level Impacts: Recognizing exactly how temperature influences membrane efficiency.

- Cleansing Methods: Routine maintenance practices protecting against fouling or scaling concerns.

- Regular Assessments: Making certain total health and wellness of the system with routine checks.

- Diagnostic Strategies: Recognizing usual issues swiftly through sophisticated analysis methods.

- Breakthroughs in Products Science: Future growths improving membrane layer effectiveness & toughness.

- Energy Performance Improvements: Minimizing energy intake while preserving high performance requirements.

- Water Conservation Conveniences: Adding significantly in the direction of global water preservation initiatives.

- Energy Intake Reduction: Lessening eco-friendly impact through efficient procedures.

As we progress into an age where sustainable techniques are critical, spiral injury RO membrane layer arrangement remains an important tool in accomplishing these objectives giving tidy water while lowering our environmental impact efficiently.

Thank you for joining us on this journey with the globe of spiral injury RO membrane layers We wish this extensive overview has actually furnished you with valuable insights right into this important technology that will continue forming our future towards a more sustainable tomorrow

FREQUENTLY ASKED QUESTION: Spiral injury RO membrane configuration

1. What is a Spiral Injury RO membrane arrangement?

A Spiral Wound Reverse Osmosis (RO) membrane configuration is a sort of membrane module used in water therapy processes. It contains a series of level sheet membrane layers that are twisted around a central tube, developing a spiral shape. This design allows for effective water flow and high surface location call in between the feed water and the membrane layer.

2. Exactly how does the Spiral Injury RO membrane layer arrangement job?

In a Spiral Wound RO system, feed water streams via the central tube, while penetrate (treated water) moves via the outer layers of the membrane layer. The focused brine service is turned down and removed from the system. The spiral style enables constant flow and decreases pressure decline throughout the membrane layer, enhancing general efficiency.

3. What are the advantages of utilizing Spiral Injury RO membranes?

The benefits include high change prices due to the big surface provided by the spiral configuration, lowered fouling due to the constant flow pattern, and convenience of upkeep as specific aspects can be conveniently changed if needed.

4. What are some usual applications for Spiral Injury RO membrane layers?

Spiral Wound RO membrane layers are extensively made use of in different sectors such as desalination plants for producing fresh water from salt water or brackish water, municipal water treatment plants for getting rid of impurities from drinking water materials, and commercial processes needing high purity water.

5. Exactly how do you tidy and maintain Spiral Injury RO membranes?

Cleaning typically includes backwashing or chemical cleansing to eliminate accumulated fouling products. Normal maintenance includes surveillance pressure goes down throughout aspects and changing them when needed to keep optimal efficiency.

6. What aspects affect the efficiency of Spiral Wound RO membrane layers?

Efficiency is affected by elements such as feed water quality (e.g., TDS levels), running pressure, temperature level, and flow rate. Appropriate selection of membrane kind and setup based on these parameters makes sure ideal treatment efficiency.

7. Can Spiral Injury RO membrane layers take care of high-salinity feed waters?

Yes, Spiral Injury RO membranes can deal with high-salinity feed waters yet may call for more frequent cleansing because of boosted fouling possible from greater TDS levels.

8. Exactly how does the spiral configuration decrease fouling compared to various other types of membrane layers?

The continuous flow pattern with the spiral style reduces fouling by decreasing stationary zones where pollutants can build up. This style additionally permits for simpler elimination of fouling products during cleansing cycles.

9. Are Spiral Wound RO membranes ideal for treating wastewater?

While Spiral Wound RO membranes are primarily used for safe and clean water manufacturing from seawater or briny sources, they can likewise be applied in wastewater therapy applications where high pureness water is called for. Additional pretreatment actions might be needed depending on wastewater attributes.

10. What is the normal life-span of Spiral Wound RO membrane layers?

The life expectancy varies relying on operating conditions but usually ranges from a number of years up to a years or more with correct maintenance and cleansing timetables.

11. Exactly how do you establish if it’s time to replace Spiral Injury RO membrane layers?

Substitute is usually shown by considerable rises in pressure drops throughout aspects with time or noticeable decreases in penetrate top quality showing reduced membrane layer efficiency.

12. Exist any type of ecological considerations when using Spiral Wound RO membranes?

Yes, there are ecological factors to consider such as energy consumption throughout procedure and potential effects on water ecosystems if not thrown away appropriately at end-of-life. Suppliers often give standards for liable disposal practices.

Dr. Tina M. Nenoff is a senior scientist and Sandia Fellow at Sandia National Laboratories, renowned for her pioneering work in nanoporous materials. Her research focuses on the chemistry of confinement and reactivity of ions and molecules within these materials, leading to significant advancements in environmental remediation and energy applications. Notably, she played a crucial role in developing crystalline silicotitanates used to remove radioactive cesium from contaminated seawater following the Fukushima Daiichi nuclear disaster.