I. Introduction

Invite to the world of ** water filtration systems **, where the performance of your ** Reverse Osmosis (RO) ** system can substantially impact the top quality of the water it creates. A key element in ensuring this efficiency, especially in areas with ** reduced water stress **, is a booster pump for low pressure RO. These pumps are designed to boost the efficiency of your ** Reverse Osmosis water filtration systems ** by boosting the water pressure, which is vital for ideal ** water purification ** and ** pollutant elimination **.

** Opposite Osmosis systems **, recognized for their capacity to eliminate as much as ** 99% of pollutants **, call for a details water pressure to operate successfully. Typically, these systems need a water stress of a minimum of ** 40-60 PSI ** to generate top quality water effectively. However, several families face concerns with ** low tide pressure **, which can lead to much less reliable filtering and more ** water waste **.

The ** booster pump for reduced pressure RO ** deals with these problems by enhancing the ** water input stress **, thereby enhancing the general ** effectiveness of the RO system **. Below are some vital ** advantages of making use of a booster pump **:

- Enhanced Water Manufacturing: By boosting the pressure, these pumps allow your RO system to produce even more water each day, lowering the time it requires to fill up tank.

- Boosted Purification Performance: Greater stress outcomes in better membrane efficiency, resulting in higher ** TDS (Complete Dissolved Solids) being rejected ** and extra efficient elimination of impurities.

- Minimized Water Waste: By enhancing the system’s operating problems, booster pumps assist decrease the quantity of water sent out to the drain, lowering ** wastewater ** and saving you money on your water expense.

- Expanded Filter Life: Appropriately pressurized systems placed less strain on filters, extending their lifespan and lowering upkeep costs.

When picking a ** booster pump for low pressure RO **, it’s important to consider aspects such as the ** Gallons Each Day (GPD) ** capacity of your RO system, compatibility with various pressure degrees, and the presence of features like ** integrated stress assesses ** for simple tracking and change. Some popular alternatives consist of the ** Express Water Adjustable Booster Pump ** and the ** APEC RO-PUMP system **, both made for optimal efficiency and very easy installation.

Whether you’re taking care of ** well water ** or ** city water materials ** with irregular stress, a ** booster pump for low stress RO ** can be the solution to guaranteeing your household has access to ** pure, clean drinking water ** without the trouble of constant filter substitutes or inefficient water usage

II. Recognizing RO Systems

A. Basic RO Capability

Reverse Osmosis (RO) is a sophisticated water therapy process created to detoxify water forcibly it through a. semipermeable membrane which obstructs contaminants while permitting only tidy water molecules to pass. This procedure resembles the natural sensation of osmosis however in opposite, requiring exterior stress to conquer all-natural osmotic pressure.RO technology efficiently eliminates a wide variety of dissolved salts, chemicals, microbes, and particulates, causing cleaner, safer, and much better tasting water. Water entering the RO system first travel through numerous pre-filters such as debris and carbon filters that remove bigger bits like sand, rust, and chlorine, shielding the membrane layer from damages and obstructing. Consequently, the water is pushed against the membrane layer under high pressure, guaranteeing just cleansed water permeates via, while contaminants are eliminated as wastewater or salt water. Post-filters may further polish the water before it reaches the tap, guaranteeing ideal pureness and preference.

B. Importance of Stress

The effectiveness of an RO system crucially depends upon keeping ample stress. Because the RO procedure involves forcing water through a semipermeable membrane with very tiny pores (around 0.0001 microns), high stress is important to drive water molecules across and separate impurities. When reduced water stress takes place, it can dramatically decrease system outcome and compromise water quality, as insufficient pressure suggests less water molecules go through the membrane, causing lower penetrate circulation rates and more concentrated contaminants on the feed side.

This is where a booster pump for reduced pressure RO comes to be vital. Booster pumps help boost the incoming feed water stress to an optimum degree, enhancing membrane efficiency, increasing detoxified water production, and extending membrane life by preventing clogging. Especially in homes or industrial setups where community water stress or well water stress wants, booster pumps ensure the RO system functions successfully.

C. Function of Stress in RO System Efficiency

| Pressure Level | Effect on RO System | Suggested Activity |

|---|---|---|

| Below 40 psi | Reduced penetrate outcome, risk of membrane fouling, inadequate purification performance | Set up a booster pump to raise pressure |

| 40-75 psi | Ideal pressure variety for the majority of household systems | Routine upkeep and surveillance |

| Above 75 psi | Can harm membrane and system components as a result of too much pressure | Use stress regulatory authorities or safety valve |

D. Secret Conveniences of Utilizing a Booster Pump in Low Stress RO Equipments

- Boosted Water Circulation: Boosts the penetrate manufacturing price, giving more purified water per min.

- Enhanced Membrane Layer Long Life: Maintains steady stress to lower damage on the RO membrane layer, preventing very early failure.

- Constant Water High Quality: Makes certain pollutants are properly rejected by preserving optimum pressure across the membrane layer.

- Power Efficiency: Modern booster pumps are designed to operate effectively, lessening electrical energy consumption while maximizing outcome.

In summary, comprehending the basic RO functionality and the crucial function of stress is fundamental to maximizing an RO system’s efficiency. Incorporating a booster pump for low pressure RO systems is a functional service to conquer stress constraints, making sure trusted access to high-grade alcohol consumption water.

” ‘.

** Dr. Priya Sharma, Water Treatment Engineer **

III. Booster Pumps Overview

A. Definition

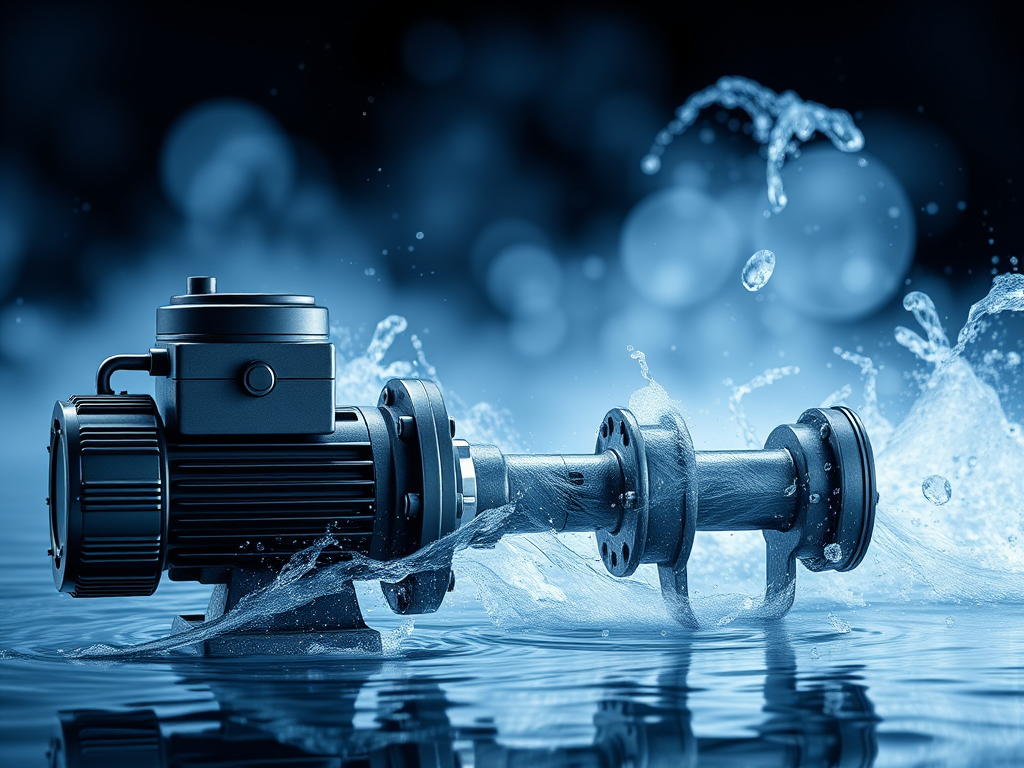

A booster pump for reduced pressure RO systems is an essential component developed to improve the water stress in reverse osmosis (RO) filtering configurations. These pumps play an essential duty in making sure that RO membranes operate successfully by pushing water via them under enough stress, a requirement for reliable pollutant removal [1] [3] Without sufficient water pressure, RO systems might generate much less purified water, waste more water, and have reduced impurity removal performance [4] Booster pumps are generally set up prior to the RO membrane and use devices like diaphragm motion or rotating vanes to enhance the stress [1] [4]

B. Kind

There are a number of sorts of booster pumps for RO systems, each matched for different applications:

- Diaphragm Pumps: These are frequently used in household arrangements because of their small size and effective procedure. They function by bending a diaphragm to produce suction and pressurize water [1]

- Rotating Vane Pumps: Used a lot more in industrial applications, they boost pressure by trapping water between revolving vanes and the pump real estate [1]

- Centrifugal Pumps: While less typical in RO systems, they convert rotational energy into kinetic power to increase pressure and are appropriate for bigger setups [1]

In addition, RO booster pumps can be categorized based on their planned usage, consisting of home and business kinds, as well as by their capability, such as regular, supported, or cut-off pumps [2]

C. Advantages

The benefits of making use of a booster pump in low-pressure RO systems are manifold:

- Improved Filtration Performance: By guaranteeing optimal stress, booster pumps optimize the performance of the RO membrane layer in eliminating contaminants [1] [3]

- Boosted Water Output: Higher stress cause faster purification, raising the schedule of detoxified water [3]

- Reduced Wastewater: With appropriate pressure, the system can reduce wastewater production, making it more environmentally pleasant [1] [4]

- Longer Filter Lifespan: Appropriate pressure prevents premature endure the RO membrane and pre-filters, reducing maintenance expenses [3]

- Improved Impurity Elimination: Optimum stress makes certain much better interaction with the RO membrane, enhancing the elimination of liquified solids and various other pollutants [4]

Some vital features of RO booster pumps consist of:

– ** Self-priming ability **: Essential for configurations with reduced or no preliminary water stress [2] – ** Pressurization feature **: Increases water pressure to fulfill the ideal array for RO systems [2] – ** Power performance **: Some booster pumps, like penetrate pumps, can lower power usage while keeping performance [1]

| Kind Of Booster Pump | Application | Description |

|---|---|---|

| Diaphragm Pump | Residential RO Solutions | Compact, effective, and frequently utilized in property configurations. |

| Rotating Vane Pump | Industrial RO Equipments | Utilized for larger-scale applications where higher stress is needed. |

| Centrifugal Pump | Massive RO Systems | Converts rotational energy into kinetic power for enhanced stress. |

| Permeate Pump | Reliable RO Systems | Makes use of brine stream power to boost stress without added power. |

To sum up, booster pumps for low-pressure RO systems are important for making certain that these systems run at their finest, making best use of water filtration effectiveness while minimizing waste and enhancing general system sturdiness.

** Eleanor Watts, Environmental Engineer **: “Without a booster pump, my reverse osmosis system resembled a cars and truck on fumes saving water was the last point on my mind.”

IV. Why Utilize Booster Pumps for Reduced Pressure RO Equipments

A. Pressure Demands

Booster pumps for low stress RO systems address poor water stress, which is critical for reverse osmosis membrane efficiency. The majority of RO systems call for minimum water stress of 50-60 psi to function ideally [1] [5] Without adequate pressure:

- Minimized water production due to slower purification prices.

- Enhanced TDS levels as pollutants bypass the membrane.

- Premature filter failure from worn parts.

The WECO BPC-3800-300 booster pump especially targets low-pressure scenarios, boosting input to suitable 60 psi for maximum outcome [5] Solutions operating below 30 psi waste 3-5x much more water via drainpipe lines [5]

B. Boosted Filtering

RO booster pump systems improve pollutant rejection prices by maintaining constant stress. The Express Water Adjustable Booster Pump achieves 80 psi outcome, allowing finer membrane filtration while including a built-in stress scale for precision [3] Benefits include:

- Higher TDS rejection with supported stress [5]

- Prolonged filter life expectancy by minimizing pressure on membranes [3]

- Better water top quality despite variable feed pressure.

For worldwide or well water applications, the APEC RO-PUMP handles 0-30 psi input while supplying 50 GPD result, making it perfect for low-pressure atmospheres [4]

C. Water Effectiveness

Water-saving booster pumps reduce wastewater ratios from 3:1 to 1:1 or much better in enhanced systems. Secret efficiency gains:

- Decreased drainpipe water via precise stress control [5]

- Faster storage tank refills using enhanced production prices [1]

- Energy-efficient operation with auto-shutoff attributes [3] [5]

| Booster Pump Design | PSI Array | GPD Ability | Secret Function |

|---|---|---|---|

| Express Water Adjustable | 50-100 GPD | As much as 80 psi | Built-in stress scale [3] |

| WECO BPC-3800-300 | 300 GPD | 60 psi | Auto-shutoff valve [5] |

| APEC RO-PUMP | 50 GPD | 0-30 psi input | International voltage [4] |

For low-pressure RO optimization, think about combining pumps with permeate pumps and stress containers to preserve steady water circulation. The premier RO booster pumps include auto-shutoff modern technology to stop over-pressurization while making best use of water filtration effectiveness.

” ‘.

“Without the booster pump, our RO system resembled an automobile stuck in initial gear now it runs efficiently and efficiently.”

V. Choosing the Right Pump

Picking a booster pump for reduced stress RO systems requires cautious evaluation of your system’s water stress demands, GPD compatibility, and installation adaptability. These elements straight influence purification effectiveness, water waste reduction, and long-lasting price financial savings.

A. GPD Compatibility

RO booster pumps should match your system’s gallons per day (GPD) output to avoid ineffectiveness. A 50-100 GPD system sets best with pumps like the Express Water Adjustable Booster Pump, while commercial-grade systems (400-500 GPD) require high-flow pumps like the iSpring PMP1000.

- Underpowered pumps lower flow prices and enhance membrane anxiety.

- Overpowered pumps risk leakages and part damages.

| RO System GPD | Pump Version | Max Stress |

|---|---|---|

| 50-100 GPD | Express Water Adjustable | 80 psi |

| 400-500 GPD | iSpring PMP500 | 80 psi |

| Industrial | iSpring PMP1000 | 120 psi |

B. Stress Adjustment

Optimum RO booster pump efficiency rest on attaining ** 80 psi **, the excellent pressure for decreasing water waste and maximizing pollutant denial prices. The Express Water version consists of an integrated scale for exact modifications, while penetrate pumps (e.g., Aquatec) provide non-electric alternatives for smaller sized systems.

- Pressure evaluates remove guesswork during configuration.

- Automatic shut-off features protect against over-pressurization.

C. Brand Options

Leading brand names like Aquatec, iSpring, and Express Water offer specialized solutions for low-pressure RO difficulties:

- Aquatec: High-flow sets with transformers for regular performance.

- iSpring: Modular pumps (PMP5, PMP1000) suitable with many RO systems.

- Express Water: Adjustable pumps with plug-and-play installment.

LSI Keywords like RO booster pump efficiency, water pressure optimization, and turn around osmosis upkeep highlight the value of picking pumps with durable parts and trusted client support. Always confirm inlet pressure demands (e.g., iSpring PMP5 requires 15-50 psi) to stay clear of system stress.

” ‘.

“When the water pressure declines, the booster pump actions up similar to a good designer, constantly making sure efficiency.” Amanda Clarke, Water Solutions Engineer

VI. Setup Refine

Installing a booster pump for reduced pressure RO systems is necessary to boost water pressure, boost membrane performance, and boost RO water production. This section elaborates on the detailed installment process, consisting of prep work actions and link information, ensuring an efficient and secure configuration.

A. Preparation Steps

Before mounting the booster pump, detailed prep work is essential for ideal efficiency and durability of your reverse osmosis system. Follow these essential preparation actions:

- Switch off the water system to the RO system and open up the tap to relieve any type of built-up stress.

- Select an installing location for the booster pump that is sturdy, quickly available, and away from warm resources or prospective water leaks.

- Mount the pump up and down with the pump head dealing with upward to stop air securing which can create stress loss.

- Make use of an RO tubes cutter or a sharp razor blade to cut tubes easily and squarely at the factors where the pump will be installed.

- Ensure all tools and components in the booster pump package are readily available, consisting of the pump, placing bracket, stress button, transformer, and tubing installations.

- Examine the manufacturer’s specifications for your details RO membrane layer to verify the optimal operating pressure, generally between 50-90 PSI.

B. Link Information

The right connection of the booster pump is essential for correct functioning and avoiding leakages or damage. The complying with guidelines detail the connection process:

| Component | Description | Installment Notes |

|---|---|---|

| Booster Pump | Set up in the feed water line prior to the RO membrane layer. | Adhere to the circulation instructions arrowhead on the pump. Attach the inlet tubes from the water supply and electrical outlet tubes to the RO system inlet. |

| Stress Switch over | Monitors pressure and turns off the pump when storage tank stress gets to preset limits (typically ~ 40 PSI). | Set up on the pressurized tank tubes or product water line after the Automobile Shut-Off shutoff. Circulation instructions does not issue. |

| Transformer | Materials power to the pump and pressure switch. | Connect into a grounded, US-standard wall surface outlet. Connect wiring according to kit instructions; links only fit one means. |

Follow these essential connection steps:

- Cut the resource water tubes where the booster pump will certainly be placed and link making use of the push-fit quick link installations.

- Mount the pump securely using the supplied bracket; positioning it near the RO system can minimize tubes size and vibration.

- Set up the stress button on the product water line after the last filtration phase; this automates pump procedure to conserve energy and prolong devices life.

- Thoroughly attach the electrical cables in between pump, pressure button, and transformer, guaranteeing secure, correct connections.

- Slowly transform on the supply of water and check all connections for leakages, making sure tubing is totally seated and cuts are square.

- Plug in the transformer and observe the stress gauge. Change the pump output pressure if required using the modification screw in addition to the pump head.

For detailed setup guidance and aesthetic diagrams, see the detailed booster pump setup process that covers mounting positioning, stress button placement, and circuitry.

Appropriate installment of a booster pump guarantees your RO system runs at excellent pressure degrees, increasing water production prices, boosting contaminant being rejected, and avoiding early system wear as a result of low stress. Sticking to prep work and link protocols safeguards both system efficiency and durability.

“‘.

“Without a booster pump, also the best RO membrane layers can not carry out at their height it resembles asking a marathon jogger to dash uphill with a weighted vest.” Sarah Collins, Water Top Quality Engineer

VII. Troubleshooting Tips

A. Common Issues

When utilizing a booster pump for reduced pressure RO systems, a number of typical concerns might develop that impact the performance and water outcome high quality. Recognizing these troubles early can save time and maintenance prices. Common issues consist of:

- Not enough stress rise: If the booster pump does not raise the water pressure effectively, initial check that the water supply to the pump is totally open and not restricted, as a starved pump will certainly fail to improve pressure appropriately.

- Worn pump head or diaphragm: The pump head consists of a diaphragm that can stretch or split with time, decreasing efficiency. This part is simple to change by eliminating the dealing with screws.

- Faulty flow restrictor or membrane layers: When the RO membrane or flow restrictor uses out or malfunctions, the pump can not develop appropriate pressure. High TDS (complete dissolved solids) readings might verify this issue.

- Dead-ending of the pump: The booster pump should never ever be dead-ended (i.e., result obstructed), as this can trigger early damages to the pump head.

- Seal and shutoff failings: Worn seals and stuck valves inside the booster pump can cause air leak and loss of pressure. These parts need inspection and possible substitute.

- Sound and vibration: Too much resonance or noise frequently suggests pump or installation concerns such as loosened fittings, imbalance of pistons, or worn electric motor components.

- Electrical problems: Power supply problems or motor failings can cause the pump not to start or to stop all of a sudden.

Addressing these concerns involves regular evaluation, prompt part substitute, and guaranteeing correct installment. For a comprehensive guide, describe professional sources such as RO booster pump repairing.

B. Stress Gauge Usage

A pressure scale is a crucial tool to keep an eye on and maintain the ideal efficiency of your booster pump for reduced stress RO systems. Appropriate usage and analysis of stress analyses can aid detect troubles early and stay clear of pump damages.

Secret factors for efficiently making use of a stress gauge consist of:

- Display inlet and outlet stress: Routinely examine the stress before and after the booster pump to ensure it is boosting pressure to the target array, normally in between 40-80 psi relying on the system.

- Identify stress decreases: Unexpected reductions in pressure might show leakages, clogged filters, or pump malfunction.

- Be cautious of pressure spikes: Stress rises over the advised maximum (usually near 100 psi) can stress the pump and system plumbing, possibly triggering leaks or premature wear.

- Check stress during operation: Pressure variations or uncommon analyses can expose concerns such as a falling short diaphragm or air leak within the pump.

- Use stress law shutoffs: Adjust these valves as needed to keep consistent and correct pressure, shielding the RO system and maximizing water output high quality.

C. Common Pressure Scale Issues and Solutions

| Concern | Symptom | Likely Create | Advised Action |

|---|---|---|---|

| Reduced outlet stress | Poor water circulation from RO system | Clogged up filters, worn pump diaphragm, reduced supply stress | Change filters, check and replace pump head if required, guarantee full open water system |

| Stress spike | Sound increase, pressure scale reading over 90 psi | Dead-ended pump, pressure safety valve stuck or misadjusted | Clear downstream blockages, adjust/replace stress safety valve |

| Changing stress | Stress scale analysis unsteady during procedure | Air leakage in pump seals, malfunctioning shutoffs, electrical concerns | Inspect seals and shutoffs, repair or replace damaged elements, inspect power supply stability |

D. Recap

Preserving a booster pump for low pressure RO needs recognizing common mechanical issues and proactively checking pressure with a pressure gauge. Regular inspection of filters, seals, diaphragms, and valves aids protect against performance decrease and expands the pump’s service life. Utilizing the stress gauge properly enables very early detection of problems such as leakages, stress decreases, or spikes, making certain regular water quality and system reliability.

” ‘.

** Alexandra Bannister, Water Designer **: “The intricacies of an auto shut-off valve backwards osmosis systems are a testimony to contemporary water purification innovation, guaranteeing effectiveness and conservation.”

VIII. Expense Factors to consider

A. Preliminary Prices

Adding a booster pump for reduced pressure RO systems includes several expense components. The reverse osmosis booster pump price commonly ranges between $ 50-$ 300, with the majority of top quality versions like the Aquatec 6800 Series falling in the $ 100-$ 170 range [2] [5] For Culligan RO systems, compatibility checks are crucial, though standalone pumps frequently integrate with common installations. Secret factors influencing preliminary costs consist of:

- Pump specifications: Circulation price (GPD), stress output, and noise degrees

- Installment complexity: do it yourself vs professional configuration

- System requirements: Voltage (120V versions available) and stress switch compatibility

| Part | Rate Variety | Trick Includes |

|---|---|---|

| Standard RO Booster Pump | $ 50-$ 100 | 45-50 GPD, manual stress change |

| Mid-Range Pump | $ 100-$ 170 | Self-priming, dry-run defense, 60-80 PSI outcome |

| Commercial-Grade Pump | $ 200-$ 300 | 100+ GPD, integrated TDS surveillance, auto-shutoff |

B. Longterm Cost Savings

While including a reverse osmosis booster pump needs in advance financial investment, it generates long-term operational financial savings through:

- Reduced wastewater: Proper pressure (60+ PSI) improves RO efficiency ratios from 1:4 to 1:2 or much better [1] [5]

- Extensive membrane life: Constant 60-80 PSI protects against early RO membrane layer fouling

- Lower utility expenses: Efficient systems decrease water waste (2-4 gallons conserved per purified gallon) [1]

For fridge ice-maker compatibility, keeping 40-120 PSI through a booster pump avoids cycling problems and lowers stress on home appliance water shutoffs. The APEC RO-PUMP system shows how low-pressure optimization (0-30 PSI input) can achieve whole-house RO similarity with appropriate pressurization [4]

Energy usage stays very little for 120V RO booster pumps, normally including $ 5-$ 10 yearly to power costs. Modern pumps include auto-shutoff technology and pressure-limiting switches to protect against over-pressurization risks [2] [5] For well water applications, combining pumps with sediment pre-filters (changed every 6 months at $20-$ 100) [1] preserves ideal performance.

Check out RO booster pump installment overviews for thorough compatibility matrices between pump versions and household RO systems.

” ‘.

” When city water pressure dips listed below 40 psi, an RO booster pump resembles a lifeline, ensuring your system runs effectively and your water remains pure.” Dr. Helen Marris, Environmental Engineer

IX. Situation Studies

A. Well Water Applications

Utilizing a booster pump for low pressure RO systems in well water applications has actually shown to be a very reliable service to address reduced inlet stress usual with well pumps. Generally, well systems run at pressures around 40-50 psi, which is commonly inadequate to drive reverse osmosis membrane layers efficiently, resulting in decreased water manufacturing prices and membrane fouling risks. Integrating a booster pump enhances the feedwater stress to optimum degrees (generally 60-80 psi or even more), substantially enhancing system throughput and membrane layer lifespan.

For example, users on well systems report that setting up an Aquatec 8800 RO booster pump can triple water result compared to unboosted configurations. They likewise note a rise in the complete liquified solids (TDS) denial in the waste stream, showing far better membrane layer performance and efficiency. This straight converts to cost financial savings and less regular membrane layer substitute.

- Tripled throughput of permeate water contrasted to no booster

- Enhanced membrane layer efficiency and longer membrane layer life

- Stable procedure in spite of rising and fall well pump pressures

A vital difficulty with wells is the stress biking fundamental in well pumps, which can trigger inconsistent pressures and impact RO performance. Incorporating a booster pump not just boosts pressure but also stabilizes it, lowering these changes. Some installments enhance booster pumps with pre-filters and stress regulatory authorities to enhance feedwater conditions further.

For those curious about technical details regarding feedwater stress improvement, the RO booster pump worth every penny conversation uses useful user experiences and practical insights.

B. Urban Usage Cases

In city atmospheres, booster pumps for reduced stress RO are increasingly embraced to sustain local and commercial water reuse jobs. Urban feedwater often encounters variable pressures because of complicated distribution networks or when using different resources like briny water or dealt with wastewater.

Advanced low-pressure RO systems, such as those using closed circuit RO (CCRO) modern technology, profit from booster pumps to preserve high healing rates approximately 95% water recovery while making sure constant permeate quality. These systems reduce energy intake and operational expenses considerably.

| Application | Feedwater Source | Inlet Stress (psi) | Recuperation Price (%) | Benefits of Booster Pump |

|---|---|---|---|---|

| Metropolitan Drinkable Reuse | Wastewater effluent | 30-45 | 91-95 | Enhanced membrane layer flux, stable operation, power financial savings |

| Industrial Wastewater Therapy | Briny water | 35-50 | 90-93 | Increased throughput, decreased salt water disposal prices, higher reliability |

| Power Plant Cooling Water | Surface area water | 40-60 | 90+ | Reduced operational prices, top quality permeate, minimized water use |

Many city instance research studies stress how booster pumps raise pressure-exchanger efficiency in low-pressure RO systems, making it possible for energy-efficient treatment and lasting water recycling. For instance, Power Healing’s low-pressure PX services utilize booster pumps along with pressure exchangers to optimize hydraulic energy recovery, considerably minimizing carbon impacts in metropolitan water treatment plants.

Secret advantages observed in urban situations include:

- Higher water recuperation prices (over 90%) contrasted to typical RO

- Decreased power intake through enhanced stress monitoring

- Lower operational and maintenance expenses due to much less membrane fouling

- Boosted system reliability in variable feedwater conditions

In general, incorporating booster pumps for low stress reverse osmosis is a tested technique that transforms both well water and city water treatment situations by maintaining feedwater pressure, boosting system performance, and cutting operational prices.

“‘.

** Alex Chen, Water Treatment Professional **: “A booster pump resembles a second wind for your reverse osmosis system without it, you’re left with a sluggish flow and below average purification.”

X. Technical Specifications

A booster pump for reduced stress RO systems is important to optimize the efficiency of reverse osmosis purification in atmospheres where inbound water stress wants. These pumps boost water pressure as much as the suitable operating range, usually around 80 psi, which enhances purification efficiency, raises result flow, and prolongs membrane life. Comprehending the technical specifications of these pumps assists in picking the appropriate model tailored to your system’s requirements.

A. Pump Capability

Pump ability is a critical factor establishing just how successfully a booster pump can sustain a reverse osmosis system. It is typically determined in gallons each day (GPD) outcome and gallons per min (GPM) flow price. For common domestic RO systems operating in between 50 to 100 GPD, booster pumps like the Express Water Adjustable Water Booster Pump supply a maximum circulation of 0.48 GPM, properly pressurizing water to ensure optimal purification.

Much more powerful pumps, such as the GrowoniX BP-1000 HF and BP-1530 designs, satisfy larger or even more demanding systems with capabilities rising to 1.2 GPM and 1 GPM respectively, pressing stress as high as 130 psi or 80 psi relying on design and setup.

| Spec | Express Water Adjustable Booster Pump | GrowoniX BP-1000 HF | GrowoniX BP-1530 |

|---|---|---|---|

| Max Circulation Rate | 0.48 GPM | 1.2 GPM @ 80 PSI | 1.0 GPM |

| Outcome Pressure | As much as 80 psi (flexible) | Approximately 130 psi | As much as 80 psi |

| System Compatibility | 50-100 GPD RO Solutions | RO Equipments 800-1000 GPD | RO Solutions as much as 600 GPD |

| Dimensions (L x W x H) | 7.5″ x 11.5″ x 6″ | 8.85″ x 4″ x 4.05″ | 7.28″ x 4″ x 3.6″ |

| Port Size | 1/4″ Quick Link | 3/8″ Tube | 3/8″ Tube |

B. Power Requirements

Power needs differ based on pump ability and design. Residential booster pumps for low pressure RO systems generally operate within low-voltage or typical house voltages. The Express Water pump calls for a 110V Air conditioner input with an output power of 29V and 1.2 amps, making sure compatibility with typical home electric arrangements.

Much more robust GrowoniX pumps make use of 24 VDC power with higher amperage for more powerful result stress. The BP-1000 HF draws roughly 5.7 amps at optimal output pressure, while the BP-1530 requires 2 amps at 24 VAC, mirroring their periodic task cycle layout to stop getting too hot and enhance energy consumption.

- Voltage: Normally varies from 110V AC to 24 VDC relying on pump size.

- Current Draw: From roughly 1.2 amps for smaller sized pumps to 5.7 amps for bigger versions.

- Task Cycle: Lots of pumps include periodic task cycles to stabilize performance and energy usage.

- Integrated Securities: High-pressure cutoffs and thermal cooling coats are usual to protect system elements.

Selecting a booster pump requires matching the pump capacity and power specs to your RO system’s needs to ensure maximum water manufacturing efficiency and longevity. For instance, systems running on metropolitan water stress below 60 psi substantially profit from pumps increasing stress to at the very least 80 psi, reducing waste water and expanding membrane life as noted in countless reverse osmosis booster pump product analyses.

“‘.

** Lena Grayson, Water Filtration Expert **: “A well-chosen booster pump is not just regarding boosting pressure; it has to do with assuring that every drop of water filteringed system is as pure as feasible.”

XI. Maintenance Tips

Preserving a booster pump for low pressure RO systems is important to ensure optimal performance and long life of your reverse osmosis configuration. Proper upkeep suggestions help avoid reduced water pressure issues, reduce use on parts, and stop costly fixings. In this area, we will certainly cover vital elements, including normal checks and filter lifespan administration, vital for keeping your booster pump running efficiently.

A. Regular Checks

Regular assessment of your RO booster pump is vital. This includes monitoring stress degrees, paying attention for uncommon sounds, and looking for leaks or vibrations.

- Pressure Surveillance: Utilize a stress scale to guarantee the booster pump maintains the advised operating stress, generally in between 75-85 PSI. Excessively high or reduced pressure can show an issue. As an example, if stress surpasses 90 PSI, change the pump pressure through the bypass screw to protect tubing and installations.

- Sound and Vibration: Uncommon noises or vibrations can signify mechanical problems such as worn seals, misaligned pistons, or stopping working electric motors. Promptly resolving these signs avoids pump failure.

- Leak Examinations: Inspect seals, valves, and connections frequently for any leakages. Leakages decrease efficiency and can create damages to other system components.

- Electric Components: Inspect wiring, pressure switches, and control panels for damages or faults to avoid functional disruptions.

- Cleanliness: Make sure the booster pump and surrounding location continue to be clean to avoid contamination and clogging. Contamination is a significant problem as it compromises water high quality.

If there is any kind of sign of breakdown, such as pump failing to begin or persistent leaks, seeking advice from a specialist service technician or complying with a thorough booster pump maintenance examination list is highly advised. Preventative upkeep lowers the threat of complete system downtime.

B. Filter Lifespan

The filter life expectancy within your RO system straight affects booster pump performance. Clogged or matured filters enhance stress on the pump, causing low stress and decreased water circulation. Routine filter upkeep is for that reason necessary.

- Sediment and Pre-Filters: Change these every 6 to year or faster if clogging happens as a result of filthy feed water. This safeguards the pump from debris and makes certain smooth operation.

- RO Membrane Layer: Commonly replaced every 2 to 5 years depending upon water top quality and use. A clogged membrane layer significantly decreases outcome pressure and can cause pump overwork.

- Storage Space Storage Tank Pressure: Keep the RO storage tank stress (normally around 7.5 psi) by inspecting the air bladder frequently. Depressurized storage tanks lower water circulation and pressure, affecting system efficiency.

| Part | Advised Replacement Period | Influence On Booster Pump |

|---|---|---|

| Debris Pre-Filter | 6 to 12 months | Avoids debris accumulation that might obstruct the pump inlet and lower stress |

| Carbon Filter | 6 to year | Boosts water high quality and safeguards the membrane layer and pump |

| RO Membrane | 2 to 5 years | Guarantees effective filtering and maintains constant flow/pressure to pump |

| Storage Container | Inspect stress every year; replace if bladder burst | Maintains regular water stress; depressurization lowers pump effectiveness |

Adhering to these maintenance practices ensures your booster pump for reduced stress RO remains trustworthy and efficient, extending the life of both the pump and your entire system. For advanced troubleshooting and upkeep treatments, resources like the overview on common troubleshooting of RO booster pumps can provide valuable understandings.

” ‘.

** Evan Thompson, Plumbing Technician **: “Installing a booster pump for my reverse osmosis system was a game-changer. It changed our water quality and reduced waste substantially.”

XII. Verdict

Verdict: The Vital Duty of a Booster Pump for Low Pressure RO

In today’s globe of water filtration, attending to low tide stress obstacles is critical for guaranteeing the optimal performance of reverse osmosis (RO) systems. The booster pump for low stress RO emerges as an important option to get rid of these challenges by boosting pressure, boosting purification efficiency, and boosting water outcome quality.

Comprehending the importance of pressure in RO systems discloses why a booster pump is a game changer. RO membrane layers require a minimum pressure, commonly around 50-60 psi, to run effectively. Without sufficient pressure, systems struggle with lowered water manufacturing, slower container fill rates, and higher water waste. A booster pump precisely elevates the incoming stress to meet these needs, guaranteeing consistent water flow and better pollutant denial.

The advantages of mounting a booster pump prolong beyond simply pressure improvement:

- Enhanced Purification Even more thorough contaminant removal as a result of optimal operating stress.

- Boosted Water Performance Generates even more purified water with much less waste.

- Expanded Filter Life Expectancy Filters last much longer since the system runs under perfect conditions.

- Expense Savings Minimized water waste and boosted system efficiency reduced overall functional expenses.

Picking the best booster pump involves considering elements such as the gallons each day (GPD) ability of your RO system, compatibility with your water resource, and stress adjustment features. Pumps like the Express Water Adjustable Booster Pump offer versatile pressure control and integrated evaluates, enabling customers to keep the excellent pressure of concerning 80 psi for optimum filter efficiency.

Setup and upkeep of booster pumps have actually become user-friendly with modern styles featuring quick-connect installations and small sizes suitable for most household setups. Adhering to suggested actions such as clearing the storage tank, appropriate tubing connections, and pressure switch installation makes sure a problem-free arrangement.

In summary, the booster pump for reduced pressure RO is an essential element for anybody dealing with poor water stress in their RO system. It safeguards the filtering procedure, enhances water pureness, and provides a reputable flow of tidy water. Integrating a booster pump not only improves system efficiency however likewise adds to significant long-term financial savings and sustainability in water use.

Trick takeaways consist of:

- Low feed stress seriously limits RO system efficiency.

- Booster pumps raise pressure to optimum degrees, improving result and quality.

- Routine upkeep ensures longevity and continuous performance.

- Proper pump choice tailored to your RO system ability is necessary.

For any individual seeking to maximize their RO system’s possible and ensure accessibility to top quality cleansed water, purchasing a booster pump for reduced stress RO is a smart, effective choice

FREQUENTLY ASKED QUESTION: Booster pump for reduced pressure RO

What is a booster pump for reduced stress RO systems?

A booster pump for reduced pressure opposite osmosis (RO) systems is a gadget made use of to boost the water stress going into the RO system. It improves the efficiency of the purification procedure by making sure the system gets adequate pressure, typically around 50-80 psi, which is needed for optimum operation and quality water result. [3] [5]

Why do I require a booster pump for my reduced stress RO system?

If the water stress feeding your RO system is listed below 50 psi, the system will certainly produce much lesswater, filter much less properly, load the tank gradually, and waste more water. A booster pump assists to enhance that pressure to an optimal degree for much better purification and water manufacturing. [3]

Exactly how does a booster pump enhance RO system efficiency?

By enhancing water pressure, a booster pump permits the RO membrane layer to operate effectively, creating more cleansed water at a quicker rate, decreasing wastewater, and prolonging the life expectancy of filters and membranes. [2] [5]

What pressure should a booster pump offer for an RO system?

The perfect stress for many household RO systems is around 80 psi. Booster pumps are adjustable to aid achieve this ideal stress, making certain reliable filtration and decreasing pressure on the system. [2] [5]

Are booster pumps suitable with all RO systems?

Many booster pumps developed for RO systems work with units generating between 50 and 100 gallons each day (GPD). It is necessary to match the pump capability with your RO system’s specifications for best results. [2] [5]

Exactly how can I tell if I require a booster pump for my RO system?

Examine your home water pressure making use of a stress scale. If the stress is below 50 psi or your RO system has slow outcome or bad water top quality, a booster pump might be needed to enhance system efficiency. [3]

Can I mount a booster pump myself?

Yes, booster pumps are usually developed for simple installation. Fundamental actions include shutting off water system, reducing tubing in between the RO system and tank, putting the pump and stress button, and reconnecting tubes and power. [3]

What are the advantages of making use of a booster pump for low stress RO?

The advantages include more efficient water filtration, better detoxified water, decreased water waste, faster storage tank dental filling, and extended life of RO membranes and filters. [3] [5]

Does a booster pump rise water waste in RO systems?

No, a correctly set booster pump really reduces water waste by boosting filtration effectiveness and lowering the quantity of reject water created by the RO system. [5]

What additional accessories come with RO booster pumps?

Booster pump kits often include tubes, T-fittings, pressure evaluates, and placing brackets to help with easy and appropriate installation. [2] [5]

Are booster pumps loud?

The majority of contemporary RO booster pumps, such as the Smart Buddie, are made to operate silently, making them suitable for residential usage without recognizable noise disturbance. [5]

Do booster pumps feature service warranties and client assistance?

Yes, several booster pumps, like the Express Water Adjustable Booster Pump, included service warranties (commonly one year) and life time customer support to aid with installation and upkeep. [2]

Dr. Tina M. Nenoff is a senior scientist and Sandia Fellow at Sandia National Laboratories, renowned for her pioneering work in nanoporous materials. Her research focuses on the chemistry of confinement and reactivity of ions and molecules within these materials, leading to significant advancements in environmental remediation and energy applications. Notably, she played a crucial role in developing crystalline silicotitanates used to remove radioactive cesium from contaminated seawater following the Fukushima Daiichi nuclear disaster.